From grain to glass

Our entire production process is considered, meticulously planned and time consuming.

Every drop of Lancaster Single Malt begins its life in the brewhouse of Lancaster brewery, utilising the expertise, equipment and production techniques used to produce the award-winning ales. Our Live Brewer's yeast, traditionally used to brew beer aids a long fermentation that develops unique flavours to the wash, producing fruity esters with lots of complexity.

Our Single Malt is matured in highly active casks that help to accelerate the ageing process, whilst add depth of flavour & complexity to our spirit. Many of the casks filled at Lancaster Spirits Co. are specially prepared to accelerate the interaction between the whisky and the wood during the aging process. Harnessing the wood in this manner helps to develop complexity within the spirit that often takes decades in traditional refill casks.

Our Single Malt Whisky, Gins & Vodkas are all produced from three ingredients, Grain, Yeast & Water in our Brewhouse

Malt Barley

At Lancaster Spirits Company, we use a winter barley called Flagon Pale Ale malt, that is crucial in shaping the flavour profile of whisky - influencing its aroma, taste and composition.

Yeast

Our live 200-year-old Lancastrian brewing yeast is arguably our most important ingredient. Once added to our wort, it kick-starts the fermentation process. Our Live Yeast combines perfectly with our pale ale malt to facilitate a slow fermentation of up to 168 hours. Helping to shape the fruity characteristics of our spirit.

Born & Brewed

Lancaster Brewery has been brewing beer in Lancaster since 2005 and our current production site has been called home since 2011. The skilled team run an incredibly tight ship and were forerunners in gaining a Salsa Accreditation, which they have held nearly a decade.

Under the experienced guidance of Will, the Head Brewer, the brewing team introduce water and malt into the mash tun. Here, is where starch in the malt is converted into sugars, creating a liquid known as "wort". This is essential for our yeast to works its magic a little later in the process.

Live Yeast

The sugary wort is transferred to a large fermentation vessel and the brewing team add a bespoke mix of our own strain of brewing yeast and distilling yeast. Both these yeast work in together to convert the sugars to alcohol.

fermentation

The wort and yeasts are given plenty of time to ferment. We wait for at least 120 hours before the wash is finally ready to be handed over to our distilling team.

True Lancastrian Spirit

From Borehole to Barrel

Our newly constructed Whisky Room sees our gleaming 3000L still, Constance, take centre stage. She sits alongside bespoke racking where our select casks will soon be taking their resting places over the coming months.

Distilling

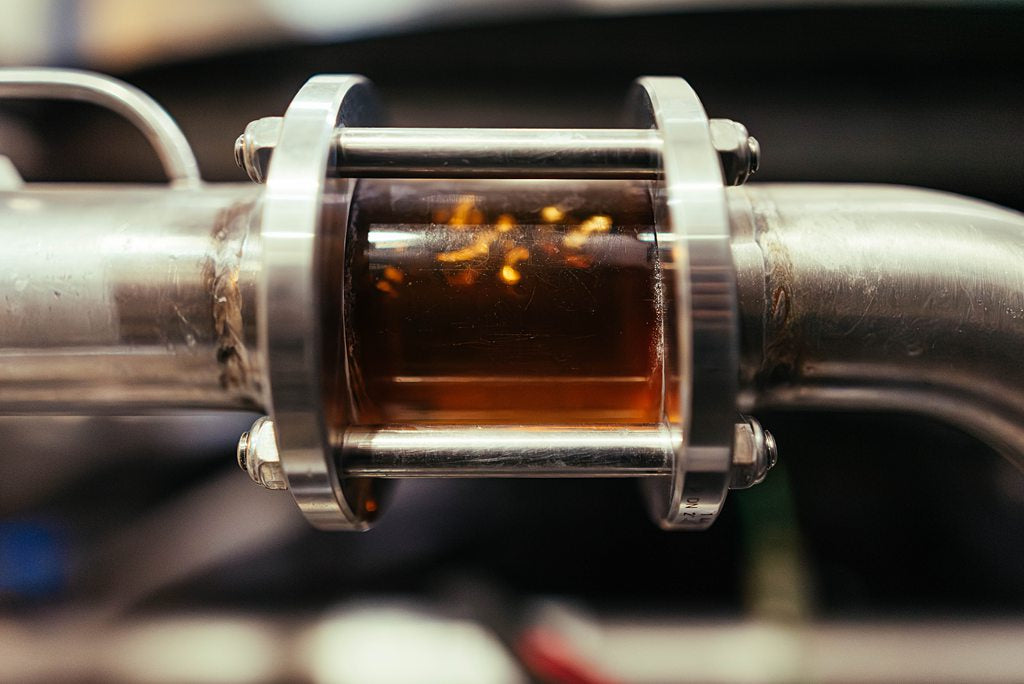

Once the water, yeast, and malt are combined in the brewhouse, the distillation process can begin.

Our copper pot stills, reminiscent of traditional Scottish designs, are pivotal in shaping the whisky’s final character. Copper’s catalytic properties help remove unwanted sulfur compounds, resulting in a smoother, more refined spirit.

Our distillation process is a blend of art and science, requiring careful control and a deep understanding of the intricate interactions between the ingredients

Maturation

Once filled, the casks take their place to rest in the Whisky Room. Our distillery team are primed to keep a watchful eye throughout the maturation period as the wood and Lancaster's climate make their marks on the spirit within.

Bottled

All our spirits are bottled on site by hand. We then label and sign each one.